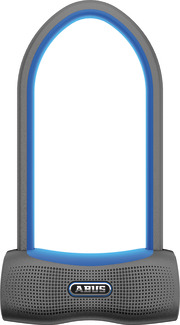

ABUS Live protected

At ABUS, we have a steadfast commitment: your peace of mind. Our primary focus is to deliver security and safety solutions that guarantee peace of mind for your residence, business, or leisure activities. For nearly a century, we have been developing security solutions for homes, diverse industries, and individuals on the move.

Since our inception in 1924, we've been crafting security solutions that safeguard homes, empower businesses, and enhance personal safety on the go. Trust ABUS to secure what matters most – because your safety is our lifelong mission.